If you own or operate a commercial beer tap system, ensuring that it runs smoothly and provides quality draft beer is crucial. Proper cleaning and maintenance are essential to avoid common problems and ensure the longevity of your beer tap system. A clean system not only guarantees the best tasting beer but also prevents equipment malfunctions that can result in waste or a loss of business. Additionally, investing in the right beer accessories can make maintenance easier and more efficient. In this guide, we’ll walk you through why proper cleaning is essential, common problems and their solutions, tools you’ll need, and a step-by-step guide to maintaining your system.

| Table of Contents Why Proper Cleaning is Essential for Your Beer Tap System Common Problems in a Beer Tap System and How to Identify Them Tools You’ll Need to Clean Your Beer Tap System Effectively Step-by-Step Guide to Cleaning a Beer Tap System Preventative Maintenance Tips for Your Beer Tap System Troubleshooting Tips for Persistent Beer Tap System Issues How to Extend the Lifespan of Your Beer Tap System |

Why Proper Cleaning is Essential for Your Beer Tap System

The beer tap system is the heart of any bar, restaurant, or home brewery, delivering refreshing draft beer to customers or guests. However, if not cleaned regularly, the tap lines, faucets, and other components of the draft beer system can accumulate yeast, bacteria, mold, and old beer residues. These elements can cause unpleasant off-flavors, sourness, and even make the beer unsafe to consume.

Additionally, dirty lines can lead to beer foaming issues, clogging, and damage to your beer tap system. It’s not just about aesthetics – improper maintenance can shorten the lifespan of your equipment and result in costly repairs. Regular cleaning and proper care ensure that you have consistent beer flow and optimal flavor for your customers.

Also Read on: Guide to Beer Accessories: Growlers, Markers, Buckets, and More

Common Problems in a Beer Tap System and How to Identify Them

A well-maintained beer tap system is critical to ensuring your draft beer is served at its best. However, even with regular cleaning, issues can still arise. Below are some common problems that can occur, along with tips on how to identify them.

1. Beer Taps Not Dispensing Properly

If you’re not getting the expected pour from your beer taps for home bar or commercial setup, it could be due to several issues. These can range from low keg pressure to blocked lines. You can troubleshoot by checking the following:

Ensure the CO2 pressure is at the correct level (generally 10-12 PSI for most beers).

Check for any blockages or kinks in the beer tap lines.

Inspect the beer keg connectors for wear or damage.

2. Foamy Beer

Excessive foam can result from improper beer tap system installation, insufficient pressure, or dirty lines. Here’s how to troubleshoot:

Verify the PSI level and adjust accordingly.

Clean your beer tap faucet and beer tap lines regularly.

Ensure that the beer keg has been chilled to the appropriate temperature (around 38°F).

3. No Beer Coming Out of the Tap

This could be due to a clogged line, a disconnect in the beer keg connectors, or a faulty faucet. To identify the issue:

Inspect the tap for blockages or buildup.

Check the keg connections for leaks or loose fittings.

Verify that the keg is pressurized and the CO2 tank is working.

BistroToRestro is the ultimate hub for commercial bar beer accessories. Shop top-notch keg couplers, drip trays, beer tap handles, and cleaning kits designed for high-volume use. Ensure smooth operations and flawless pours with our premium products tailored for professional bars.

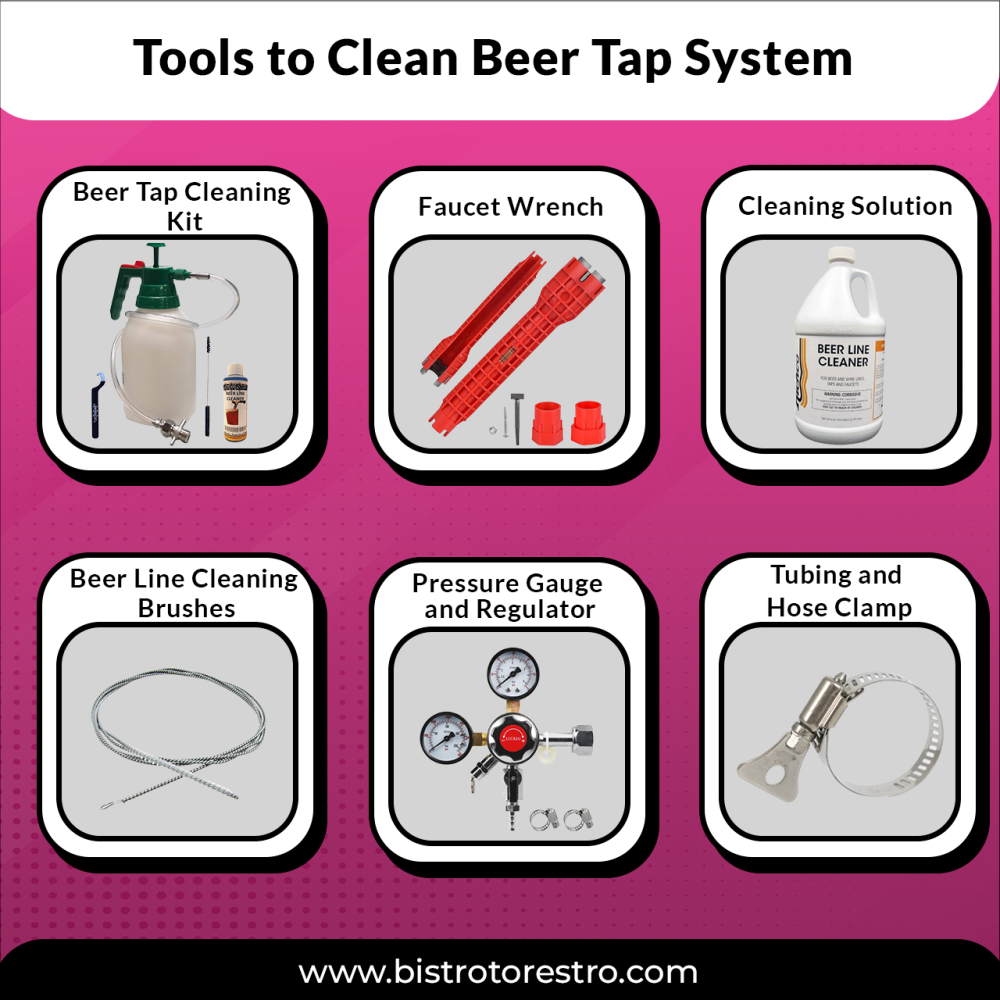

Tools You’ll Need to Clean Your Beer Tap System Effectively

Cleaning your draft beer system properly requires the right set of tools. Here’s a list of essential equipment to get the job done:

1. Beer Tap Cleaning Kit

A beer tap cleaning kit typically includes brushes, cleaning solution, and a special faucet cleaning attachment. These kits are specifically designed for cleaning beer tap lines and faucets.

2. Faucet Wrench

A faucet wrench is useful for disassembling beer taps for home bar or commercial faucets when you need to deep clean the faucet or replace parts.

3. Cleaning Solution

You’ll need a non-corrosive, food-safe cleaning solution designed for beer tap cleaning. Many breweries and bars use alkaline cleaners or specialized solutions to remove yeast and residue build-up.

4. Beer Line Cleaning Brushes

Brushes for cleaning beer tap lines can be used to scrub away any residue or build-up inside the beer lines. They help ensure a thorough clean and are essential for maintaining optimal beer flow.

5. Pressure Gauge and Regulator

A pressure gauge is necessary for checking the PSI in your beer tap system and ensuring the pressure is within the ideal range. The regulator is used to adjust the CO2 pressure to the correct level for beer dispensing.

6. Tubing and Hose Clamp

Having extra tubing and hose clamps on hand allows for quick repairs and replacements of damaged lines or connections.

Step-by-Step Guide to Cleaning a Beer Tap System

To keep your beer tap system running efficiently, cleaning should be performed at least once a month, though it may need to be done more often depending on how frequently the system is used. Here’s a step-by-step guide to ensure your system remains in top condition.

Step 1: Turn Off the CO2

Before beginning any cleaning procedure, disconnect the CO2 tank and relieve the pressure from the lines to prevent any pressure buildup or accidents during the cleaning process.

Step 2: Disconnect the Keg and Remove the Faucet

Detach the keg and beer keg connectors. Remove the beer tap faucet using a faucet wrench and set it aside to clean.

Step 3: Clean the Faucet

Soak the faucet in the cleaning solution and scrub it with a brush to remove any buildup. If you notice any stubborn residues, use a specialized cleaning beer tap faucet solution to break down the grime.

Step 4: Clean the Beer Lines

Insert the cleaning solution into the beer lines using a beer tap cleaning system or dedicated beer line cleaning tool. Run the solution through the lines and let it sit for 15-20 minutes to break down any yeast and beer residue. Afterward, flush the lines with clean water to remove the cleaning solution.

Step 5: Clean the Coupler and Keg Connectors

Take apart your beer keg connectors and clean them using the same cleaning solution. Use a brush to scrub away any dirt or beer residues. It’s crucial to clean these components to avoid contamination.

Step 6: Reassemble the System

After everything has been cleaned and dried, reassemble the system, reconnect the keg, and check for leaks.

Step 7: Check the System’s Functionality

After reassembly, turn on the CO2 tank and adjust the PSI. Test the beer taps to ensure proper flow and check for any signs of foaming or leaks.

Preventative Maintenance Tips for Your Beer Tap System

To minimize the need for frequent repairs and troubleshooting, regular beer tap maintenance is key. Here are some tips to help you maintain your beer tap system:

1. Regularly Inspect Components

Conduct routine inspections of all components, including the faucets, keg connectors, and lines. Look for signs of wear, leaks, or clogs.

2. Replace Worn Parts

Over time, certain parts like O-rings, seals, and washers can deteriorate. Replace these components regularly to prevent leaks and malfunctions.

3. Maintain Proper Pressure

Always ensure the CO2 pressure is properly calibrated for the beer type you are dispensing. Too high or too low pressure can cause foaming or poor flow.

4. Keep the Beer Keg Refrigerated

Store the beer keg in a beer tap refrigerator at the correct temperature (around 38°F). This ensures the beer stays fresh and dispenses properly.

Troubleshooting Tips for Persistent Beer Tap System Issues

Even after cleaning, you might face persistent issues with your beer tap system. Below are some tips to address recurring problems:

1. Foamy Beer

If the foam problem persists after cleaning, check the temperature of the beer. Beer poured at temperatures higher than 40°F can cause excessive foam. Also, check for over-carbonation in the keg.

2. Low Beer Flow

If the beer flow is still weak, inspect the beer keg connectors for any obstruction. Additionally, ensure that your beer lines are free from kinks or damage.

3. Leaky Faucets

A leaky faucet may be the result of a damaged washer or an unclean tap. Replacing the faucet components and giving the faucet a deep clean should resolve this issue.

How to Extend the Lifespan of Your Beer Tap System

To maximize the longevity of your beer tap system, it’s essential to incorporate the following practices:

Clean regularly: Cleaning yourbeer tap lines and faucets frequently prevents build-up that could cause blockages or off-flavors.

Inspect for leaks: Addressing leaks early helps prevent damage to your equipment.

Store kegs properly: Ensure that kegs are kept in cool, refrigerated environments to maintain optimal beer quality.

Replace worn-out components: Regularly replace components like O-rings and washers to avoid malfunctions.

A well-maintained beer tap system is vital for any bar, pub, or home brewer aiming to provide high-quality draft beer. By following the tips in this guide, you can ensure your system remains clean, functional, and ready to serve great beer every time. Remember that regular cleaning and beer tap maintenance not only ensure optimal beer quality but also extend the lifespan of your equipment. Troubleshooting common issues, using the right tools, and staying on top of preventative measures can save you time, money, and the hassle of a malfunctioning draft beer system.

FAQs

Why is my beer tap not working?

Your beer tap system may not be working due to low pressure, blocked lines, or a faulty keg connection. Ensure that the CO2 is set correctly, and inspect the system for leaks or clogs.

Why is there no beer coming out of my keg?

No beer may be coming out because of a loose or damaged beer keg connector, low CO2 pressure, or a clogged line. Inspect these components and ensure they’re functioning properly.

How do I unclog a beer tap line?

Use a beer tap cleaning kit to flush the line with a cleaning solution, or manually use a beer line brush to remove any residue.

What PSI should beer taps be at?

The ideal PSI for most beer tap systems is between 10-12 PSI. However, this can vary depending on the type of beer, the length of the lines, and the temperature. Always adjust accordingly for optimal flow.